Xmind Copilot brings structure to AI-generated content [REVIEW]

Mind Mapping Software

AUGUST 5, 2023

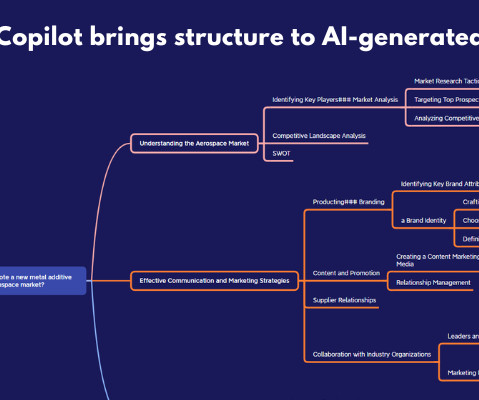

The tags it inserts next to each heading enables it to be imported into almost any platform that manages articles – such as a WordPress blog. If it’s not tagged, it’s treated as unformatted paragraph wording. Here’s what the markdown output of my additive manufacturing mind map looks like (image at right).

Let's personalize your content